Grasselli

Our Brands

NSL 400/600

SLICER

Vertical meat slicer for obtaining perfectly even slices of bone-in or boneless meat, thanks to the Grasselli multi-blade cutting system.

Extreme precision even for thinner slices, and high yields: a technologically advanced solution for processing fresh meat.

BENEFITS

- Optional quick blade changing system for replacing the entire set of blades in just a few minutes.

- No tools needed to prepare for the cleaning process, sanitation and blade replacement.

- Adjustable cutting parameters to allow the maximum quantity of product to be sliced.

- Possibility to slice bone-in meats without chipping.

- Possibility to cut also crust frozen meats with a temperature of -4/-5 degrees.

- Extremely versatile with a wide range of cutting options.

- Cutting-edge design with continuous welding and rounded edges to ensure greater hygiene.

- Special solutions available on request (such as cutting chambers with differentiated cutting thicknesses).

TECHNICAL SPECIFICATION SHEET

- Cutting capacity up to 2,000 kg/h depending on the product conditions.

- Possibility to cut both boneless meats (minimum thickness 2.5 mm) and bone-in meats.

- Sectioned meat pressing system for cutting bone-in products on the BI version.

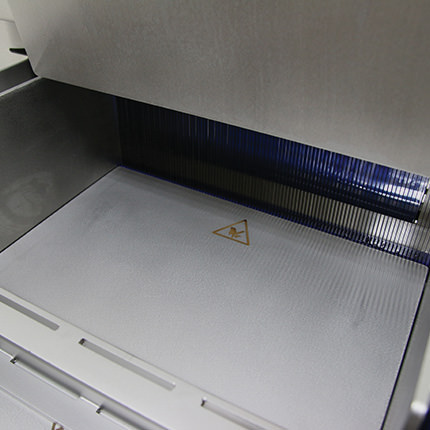

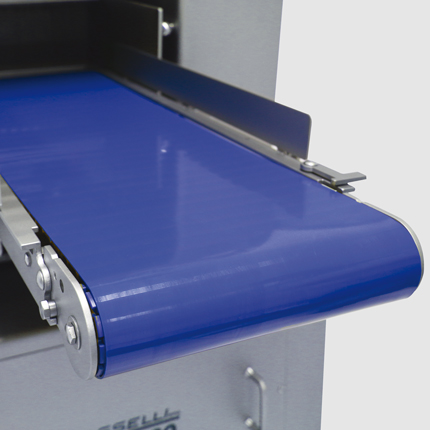

- NSF certified outfeed conveyor belt.

- Automated blade tension adjustment system.

- Built-in automatic lubrication system.

- Frame in food-grade non-radioactive Stainless steel.

TECHNICAL DATA

| Height: | 1410 mm – 55.50″ |

| Width: | 986 mm – 38.82″ |

| Depth: | 1450 mm – 57.09″ |

| Weight: | 590 Kg – 1300 lb |

| Motor power: | 4.2 / 5.5 Kw |

| Noise level: | 68 db |

| Working width: | 396 mm – 15.59″ |

| Maximum product height: | 180 mm – 7.09″ |

| Minimum slicing pitch boneless meat: | 2,5 mm – 0.09″ |

| Minimum slicing pitch bone-in meat: | 10 mm – 0.39″ |

| Air consumption: | 30 lt/min |

DOWNLOADS